How Turbochargers Work in Tractor Engines – A Farmer’s Guide

A turbocharger (or “turbo”) is a device on a tractor diesel engine that uses the engine’s own exhaust flow to force extra air into the cylinders. In simple terms, a turbo is like a small windmill driven by exhaust gas; it spins a compressor wheel that pushes more air (and oxygen) into the engine. By packing in more air, the engine can burn more fuel in each stroke, so it produces more power from the same size engine.

Turbocharged vs. Naturally Aspirated Engines

A naturally aspirated (ordinary) diesel engine draws in air at normal atmospheric pressure. A turbocharged diesel engine uses forced induction (a turbocharger) to increase air intake. Here’s how they compare:

- Higher Power and Torque: A turbo allows a smaller engine to produce power similar to a larger one. For example, researchers observed a 22% torque increase after adding a properly tuned turbocharger. A 6700 CC turbo diesel can match the performance of a larger non-turbo engine. Typically, turbocharged diesel engines deliver 20–30% more horsepower and pulling strength.

- Better Fuel Efficiency for the Same Work: With more complete fuel combustion, a turbo diesel tractor can do the same job using less fuel. In field tests, a turbocharged engine used about 21 liters/hour compared to 25 liters/hour for a naturally aspirated engine—saving 15–20% diesel per task.

- Low-Speed Torque: Turbos enhance low-end torque, providing strong pulling power at lower RPMs. This is ideal for farm equipment pulling plows, trolleys, or heavy implements.

- Complexity and Maintenance: Turbo engines have more components like the turbo housing, oil lines, and wastegate. They operate at high speed and temperature, requiring quality oil, timely changes, and proper cooling. Poor maintenance can cause turbo failure.

- Reliability: While simple engines are known for durability, modern turbo diesel engines are built for boost. With stronger pistons, better bearings, and upgraded cooling, well-maintained turbo tractors can last as long—or longer—than their non-turbo counterparts.

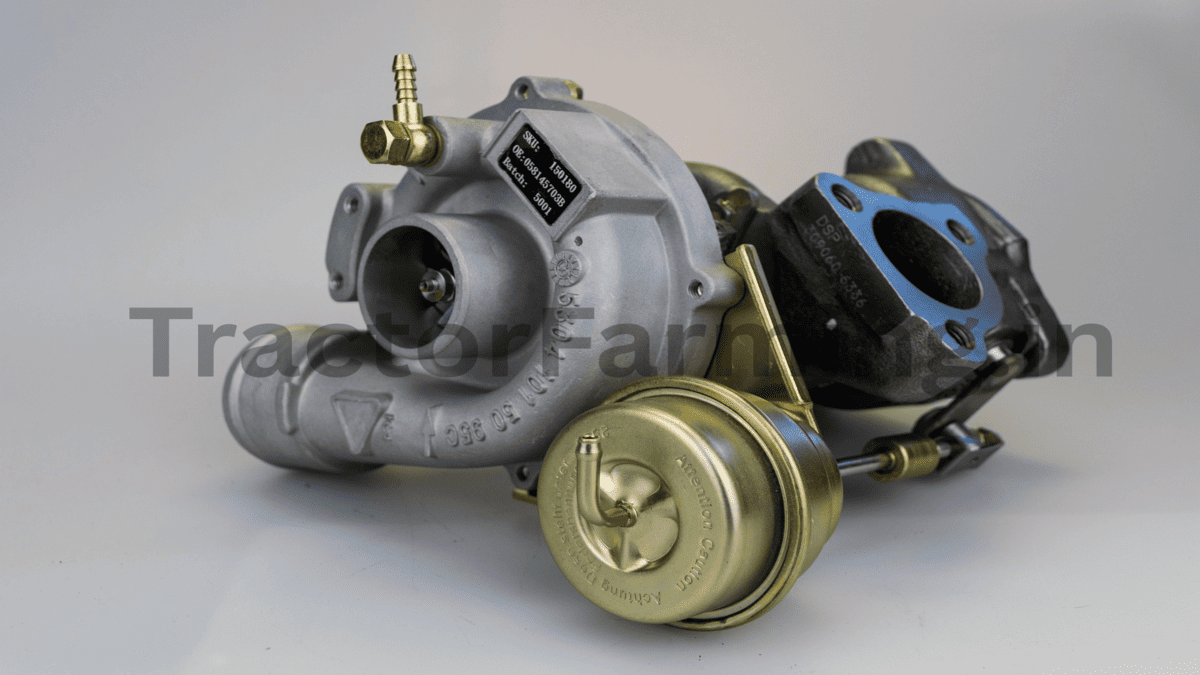

How Does a Turbocharger Work?

Hot exhaust gases (red arrows) exit the engine cylinders and spin a turbine inside the turbocharger. This turbine is connected to a compressor (blue arrows) on the same shaft. As the turbine turns, the compressor pulls in fresh air and compresses it into the engine’s intake manifold. This pressurized air increases oxygen in the combustion chamber, helping the engine "breathe" more powerfully without increasing its physical size.

Think of a turbo as a windmill in the exhaust that powers a fan to force air into the engine. Some turbos also use a waste-gate valve to control the boost level by letting excess exhaust bypass the turbine when needed.

Who Needs a Turbo? (Horsepower and Installation)

Turbochargers are most effective on medium to large diesel tractors. Smaller models (20–30 hp) usually stay naturally aspirated. Tractors above 50–60 hp typically come with factory-installed turbos. Many farmers retrofit turbos on older models under 80 hp to boost power. For example, a 75 hp engine can be upgraded to about 90 hp with the right kit and tuning.

Why Use a Turbocharger?

In agriculture, the key benefits of a turbocharged engine are more power and better fuel efficiency. Turbo tractors handle heavy implements and tough field conditions (mud, slopes, altitude) better. That means more acres covered per hour and less diesel per task. A turbo ensures cleaner combustion, boosting overall engine performance and reducing fuel waste.

Key takeaways: Turbo diesel engines offer 20–30% more horsepower and torque, improved fuel economy per job, and better load performance. This is achieved without increasing engine size—just by boosting airflow and combustion.

Fuel Efficiency: Does It Save Diesel?

Yes—when doing the same amount of work. A turbocharger helps burn fuel more efficiently, so you get more energy per liter of diesel. In tests, a turbo engine burned about 20% less diesel for the same task (21 vs 25 liters/hour). While overall fuel use may rise if you take on bigger tasks, fuel consumption per unit of work drops significantly.

Power Gain: How Much More Power?

The power increase depends on the turbo system and engine tuning, but gains of 20–30% are common. One study showed a 75 hp tractor reaching 82 hp (a 23% gain) after turbo installation and fuel adjustment. This translates to more pulling strength, faster work, and better performance across various farming operations.

Effect on Engine Life and Maintenance

Modern turbo diesel tractors are built to handle extra stress. They use reinforced components and advanced cooling systems. When maintained properly (with timely oil and filter changes and cooldowns), turbocharged engines can last over 10,000 hours. Neglect, however, can cause the turbo to fail. Regular service and clean oil are critical for a long-lasting engine.

As long as you follow manufacturer-recommended maintenance, your turbocharged engine will perform reliably for years—many factory turbo tractors serve farms for decades.

Factory Turbo vs. Adding a Turbo Kit (Pros and Cons)

Factory Turbo: Tractors with built-in turbo systems are pre-engineered for boost. Components like the intercooler, exhaust, and fuel system are factory-matched, ensuring reliable performance. These setups usually come with warranty coverage.

Aftermarket Turbo Kit: You can install a turbo on older, non-turbo tractors. These kits include a turbo, pipes, and installation instructions. With proper tuning (especially the fuel pump), you can expect noticeable power gains.

However, installing a turbo requires mechanical skill. You need to connect oil lines, modify the exhaust system, and adjust fuel delivery. If you skip fuel tuning, you won’t see the expected power increase. Done poorly, a retrofit might cause engine stress or provide limited benefit.

Pros of Turbo Kits: Affordable upgrade, more power without buying a new tractor, suitable for 50–80 hp machines.

Cons of Kits: Needs expertise for setup, may void warranties, can shorten engine life if neglected or installed incorrectly.

Summary for Farmers

A turbocharger lets your diesel tractor engine produce more power and pull heavier implements by using exhaust energy to push extra air into the cylinders. Most modern tractors above 50–60 hp are turbocharged because they deliver better performance and fuel efficiency.

With a turbo, your tractor can complete tasks faster and more efficiently. Just remember to maintain it properly—change oil regularly and avoid engine shutdown right after heavy use. If you’re upgrading an old tractor, make sure to choose the right turbo kit and tune the fuel system correctly. When installed and maintained well, a turbocharged diesel tractor is a cost-effective way to improve farm productivity and save diesel over time.